Cocoa as raw material

The bean and the tree

Cocoa products are made from cocoa beans, the kernels of the cocoa fruit. These fruits sprout directly from the trunk and the thicker branches of the cocoa tree. In the wild these trees can grow to a height of 15 metres. In cultivated forms they are kept shorter, up to 4 or 5 metres, in order to facilitate harvesting. Cocoa beans grow throughout the year, with thousands of small flowers.

Only between twenty and forty of these flowers develop into fruits, approximately 20 cm long and 10 cm wide.

Each fruit contains approximately forty seeds. These are the actual cocoa beans with a weight of about 1 gram each. The beans are white at the time of harvesting, when they are collected together with the fruit pulp and covered as the pulp subsequently becomes hot and starts to ferment.

During fermentation the distinctive aroma is created, while the bean turns dark brown. After fermentation the beans are dried, preferably in the sun. This is and will remain the best method. The dried beans are put into sacks and taken to port for shipping.

The unique taste and colour

The taste of cocoa is unique. It possesses a delicious aroma, used in many food products for extra flavour and colour. The best-known, but certainly not the only, cocoa product is of course chocolate, which is made from cocoa mass (or “cocoa liquor”), cocoa butter and a sweetening agent, usually sugar. In reality the type of bean and the drying process are not the only determinants of the final colour and taste. The manufacturing process also has a strong influence on the ultimate product. The colour of cocoa powder, for example, may vary from light orange-yellow to dark reddish brown.

An indispensable natural product

There was a time when physicians attributed special medicinal properties to cocoa, as they did to tea and coffee. But in more modern times we consume this product of nature mainly because of its taste. Whereas cocoa mass is the main ingredient of chocolate (in the form of chocolate bars, chocolate vermicelli, or bonbons), cocoa powder is the ideal flavouring agent (in ice cream, dairy products, bread spreads, biscuits and sweets). Cocoa provides the finishing touch to food products ranging from special confectionary to cappuccino coffee and is processed in numerous other food products. After vanilla, the cocoa aroma is the most popular in the western world. In addition, cocoa has a double purpose: it adds flavour as well as colour. In short, cocoa products have become an indispensable part of our diet.

A healthy source of energy

A healthy source of energy

Apart from its taste and flavour, cocoa is nutritious. The edible part of the cocoa bean – the ‘nib’ or kernel – contains about 55 % fat (with 36 % monounsaturated and 4 % polyunsaturated fatty acids) and 25 % carbohydrates. After roasting the nib contains approximately 12 % protein, 5 % water, 3.5 % minerals and vitamins, and 1.3 % theobromine. Cocoa powder contains a high proportion of natural fibre (nearly 30 %) and a relatively low number of calories (between 200 and 300 Kcal per 100 grams, depending on the percentage of fat).

From xocolatl to chocolate

The indigenous inhabitants of South America have known the secrets of the cocoa bean for over three thousand years. Columbus discovered the beans during his fourth voyage to the new world. When the Spanish conquistador Hernan Cortes conquered Mexico in 1521, he stole the recipe for ‘xocolatl’, a cocoa drink, from the Aztecs. The Aztecs customarily fermented and dried the cocoa beans, rubbed them into a powder and mixed them with water and herbs. This drink was so popular that cocoa beans served as a local currency. The conquistadors introduced the cocoa drink to the Spanish court, where sugar or honey were added.

Food of the gods for the people

For more than a century the Spanish managed to keep the recipe secret, but from the seventeenth century onwards the use of cocoa spread throughout Europe. First to the European royal courts, then to the well-to-do, and finally to the common people. At the end of the seventeenth century the drinking of cocoa had become so entrenched as a stimulant and medicine that it was even taxed. The world trade in cocoa was already at that time firmly in the hands of Dutch merchants. From the eighteenth century onwards this was also the case for the production of cocoa ‘cakes’, that is, a non-liquid form of cocoa mass, to which sugar has been added. In his botanical classification system, the botanist Linnaeus gave the cocoa tree the name Theobroma (food for the gods).

The inventors

The beginning of the nineteenth century saw a revolution in the cocoa industry. Coenraad Johannes van Houten, of Amsterdam, came up with two important inventions. In 1828 he patented a method of pressing most of the fat out of the cocoa mass, which eventually yields cocoa powder and cocoa butter. He also thought of a method to enhance the taste and colour during the production process through alkalization.

These two inventions prepared the way for the Englishman John Fry, who invented (pure) chocolate in 1847. Chocolate is a product that remains solid at room temperature but has a melting point below body temperature. It also has a richer taste and is milder than drinkable cocoa made from cocoa cakes. In a short time, chocolate conquered the world and made cocoa important as a raw material. In 1875 the Swiss chemist Henri Nestlé invented milk chocolate. The wrapped chocolate bar was again a Dutch invention.

Only if it carries the name chocolate

Apart from cocoa, chocolate also contains a sweetening agent, usually sugar. For this reason chocolate bars are often used as compact sources of energy. Chocolate is popular as an appetite depressant and a standard part of survival rations. In many European countries (including the Netherlands) chocolate can only be called chocolate if it contains a certain minimum percentage of cocoa ingredients. In addition, no fats other than cocoa butter are allowed in the processing of chocolate. If the end product does contain such fats the result must be called ‘cocoa fantasy’ or ‘cocoa substitute’. White chocolate does not contain cocoa mass, but only cocoa butter, sugar, milk and vanilla.

There is no accounting for taste, or quantity!

The taste of chocolate varies from country to country. The British mainly like creamy milk chocolate, whereas the French prefer the taste of pure chocolate, and the Americans are bulk consumers of candy bars. The Dutch have no clear preference, although older people more often prefer pure chocolate and the young like milk chocolate. The top consumers of cocoa in the world are the Belgians (5.89 kg per capita per year), the Swiss (5.67 kg) and the Germans (4.22 kg).

Cultivation, Trade and Transport

The cultivation of cocoa

Cocoa trees grow exclusively in areas that meet certain specific conditions. The cocoa belt is an area of land around the equator between 20 degrees latitude north and south. Most cocoa even grows within 10 degrees of the equator.

The soil has to be fairly loose and the climate humid. Temperatures must be between 18 and 30 degrees Celsius, with precipitation fairly constant and minimally 1,000 mms per annum. Cocoa trees must not receive too much sun, nor too much shade. Cocoa cultivation is possible up to about 1,000 metres above sea level, but most cocoa is grown below 300 metres.

The cocoa producing countries

Cocoa cultivation initially spread into the immediate vicinity of the original habitat of the cocoa tree: from Brazil and Mexico to Central America and the Caribbean area. In the sixteenth century, the Spanish introduced cocoa to the Indonesian archipelago, as well as to West Africa, which now accounts for more than half of the yearly world crop. In Southeast Asia, production has also markedly increased.

Cocoa is grown in more than thirty-five countries. The cultivated area covers between 3.5 and 4.5 million hectares. This area yields an annual production of approximately 3,5 million tons of cocoa beans. The most important producing countries of cocoa beans are:

| Ivory Coast | 2.019 thsd tons |

| Ghana | 970 thsd tons |

| Indonesia | 290 thsd tons |

| Ecuador | 270 thsd tons |

| Cameroon | 240 thsd tons |

| Brazil | 174 thsd tons |

| Nigeria | 230 thsd tons |

| Peru | 110 thsd tons |

| Dominican Republic | 75 thsd tons |

Source: ICCO, 2016/17

A vulnerable crop

Climatic conditions have a strong influence on the size of the crop. All the conditions mentioned earlier restrict the number of areas where the cocoa tree thrives. In the past there have been attempts to grow cocoa in other areas, but although initially appearing to be successful, these attempts proved fruitless. Frost, epidemics and insect plagues sometimes destroyed entire plantations in a very short time. Apart from being choosy as regards location, soil conditions and climate, the cocoa tree is susceptible to plant diseases, fungal infections, and infestation by insects or rodents. This is the reason why modern plantations devote so much attention to crop protection. An efficient modern plantation is capable of producing around 1,500 kilos per hectare. This is more than four times the average yield of three hundred years ago.

Three subspecies of nursery stock

As a result of difference in soil, climate and cultivation cocoa beans possess different properties. The three main nursery subspecies are criollo, forastero and trinitario. Each of these subspecies has its own characteristics. Criollo is lighter and more delicate, with a fine aroma. Forastero has a high yield, withstands differences in climate more effectively and therefore has become the most prominent grade. Trinitario is a hybrid form of criollo and forastero. It is wrong to say that one subspecies of cocoa tree is superior to another. Each type has its own chemical and physical properties. Moreover, cocoa, like coffee for example, is far from uniform as a raw material. The manufacturer’s art is to blend various types of cocoa beans so as to guarantee products of a consistent high quality.

What is a good consignment of beans?

A good consignment or lot consists of fully fermented cocoa beans of reasonably uniform size. Such lots contain few broken beans, insects or husks. Every lot has to be checked for taste, aroma, colour, size, fat content, mould, husk percentage and other impurities. All these factors codetermine the market value of a consignment. It goes without saying that supply and demand on the world market are the main pricing factors.

Supply and demand: the cocoa trade

In the producing countries, local traders and central sales organisations prepare cocoa for export. In these countries traders, buyers, brokers and agents carry out their trade and together form the marketing parties who agree about quality, the time and place of delivery, and about quantities. Since supply is extremely vulnerable to climatic changes, the price of cocoa may rise or fall considerably during the year. Buyers – i.e. the cocoa processing industry and its clients – naturally wish to protect themselves against such price fluctuations. The futures market in cocoa owes its existence to these uncertainties.

The futures market

The world price of cocoa is determined by the futures market. Without having to conduct personal meetings, buyers and sellers are able to conclude contracts about future deliveries of cocoa beans on the so-called futures market. At the time of negotiation the cocoa beans in question usually have not even begun to grow, and so this not yet existing cocoa provides an opportunity for a lively and exciting world-wide trade. The contracts are registered with the Clearing House. Via this agency a delivery commitment can be nullified by completion of a sales contract for the same quantity and month of delivery. The Clearing House settles the differences in price. The most important futures markets are in London and New York. Price trends can be closely followed anywhere in the world.

Trade as a market factor

Not infrequently cocoa beans travel half the world before being processed. Therefore it comes as no surprise that the international cocoa trade plays such an important role in bridging differences in time, place and price. Producers like to sell when the price is high, and buyers prefer to buy when the price is low. Between these two there is the trader, who is prepared to buy at high prices and to sell when prices are falling. This may seem illogical, but by means of futures market contracts traders cover themselves against risks. In this way they protect themselves, their suppliers and their buyers against price fluctuations, while making money in the bargain. Traders provide their clients with additional services, for example, by financing transactions in advance on behalf of their suppliers or buyers; or by securing certain types of cocoa for their clients, which the latter, without interventions, might have bought under less advantageous conditions.

An important source of income

As a raw material, cocoa is an important source of income for many producing countries. However, yields can vary from year to year. It is not surprising therefore that the governments in these countries are closely involved in the ups and downs of cocoa production and its export, and that international treaties have been concluded in support of these countries, of which the Treaty of Lomé is the best-known example. In this treaty the European Union commits itself to refrain from levying import duties on cocoa imports from a number of producer countries. In the past, attempts have been made to stabilise the price of cocoa by including long-range price agreements in treaties between producer and consumer countries. However, such treaties have proved not to work very well in practice. In the early 1990s, some West African nations privatised their raw materials industry, and this process is still continuing.

Transport and storage

The safeguarding of cocoa bean quality requires special measures. The hot, humid climates of the countries of origin are not ideal for storage and processing.

Traditionally cocoa beans were shipped in sacks made of strong jute fabric. In the last few years bulk transports, in which the cocoa is loosely dumped into containers, have grown in importance. It is expected that the majority of cocoa transports will eventually take place in this modern form, with important consequences for the cocoa trade as well as for the loading and unloading of ships.

An ideal location

The cocoa ports must be favourably situated vis-à-vis the cocoa-processing industry. Amsterdam is such a location. This is one of the reasons why the Amsterdam region is the largest cocoa entrepôt in the world.

Warehousing companies

On arrival the warehousing companies check the loads for quality and/or weight, by taking samples of each consignment and separating the damaged parts. These companies also handle the completion of documents and the settling of possible damages. The sacks or containers are stored in warehouses or are directly transhipped to the cocoa processing industry. Also, in the modern silos of today cocoa blends can be produced to the client’s specification. Transport is by road, rail or water.

Apart from the logistical side, warehousing and inspection companies have other important functions. Their sheds also contain, under rigorously controlled conditions, stored consignments for the London futures market – the London International Financial Futures and Options Exchange (LIFFE). It is not surprising therefore that the warehousing companies are well-known for their reliability and knowledge of the logistics, as well as for their flexibility.

The production process – from cocoa beans to semi finished products

From bean to mass

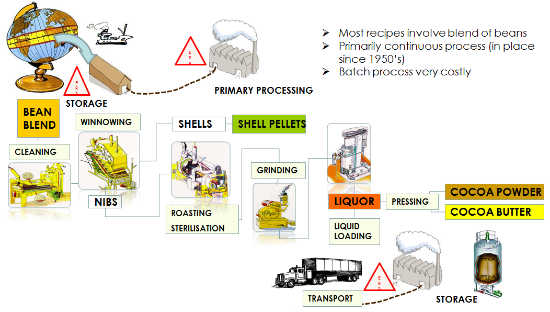

The processing of raw cocoa beans into cocoa mass implies a number of stages. Before arriving at the factory the raw cocoa beans have been fermented and dried, while during transhipment the first quality control has taken place in the port.

On arrival at the processing factory the beans are subjected to another thorough inspection, thereafter to be cleaned, mixed into the desired blend, fragmented and stripped of their husks. What remains is the inner part of the kernel, called ‘nib’. The nibs are heat-treated to eliminate possible bacteria and subsequently roasted and ground into a liquid cocoa mass. The nibs are alkalized before, during or after the roasting process. This determines the colour and taste of the cocoa mass, which, as an intermediate or semi finished product, is supplied to the chocolate industry and is also the basis for the production of cocoa powder and cocoa butter.

From mass to butter

Fat is pressed out of the cocoa mass under high pressure (up to 550 kg/sq.cm). The butter is subsequently filtered, to remove the last remnants of solid cocoa ingredients. The manufacturer supplies the cocoa butter in liquid form in tankers, or in solidified form in cardboard boxes. This product is an important ingredient of chocolate.

If the client so wishes, cocoa butter can be made odourless by means of steam and vacuum extraction. The chocolate industry’s demand is usually for cocoa butter with a neutral taste. Cocoa butter is also used in the production of cosmetics and toiletries.

From mass to powder

What remains after the removal of the cocoa butter through pressing are cocoa cakes, disks with a thickness of approximately five centimetres. These cakes are broken up and ground into a fine cocoa powder. Each manufacturer supplies its own type of powder, with its own distinctive colour, aroma, pH-value (degree of acidity) and fat content. The powder is the substance which contains the aroma, taste and colour of cocoa. That is why it is the ingredient which is added to numerous food products for flavour and colour: biscuits, puddings, deserts, creams, filled chocolates, ice cream etc. Mixed with sugar and diluted with milk it turns into a mild chocolate drink. It also provides the finishing touch for confectionary, truffles and cappuccino coffee, while new applications are being made all the time.

From mass and butter to chocolate

Chocolate is made from cocoa mass, with sugar, cocoa butter and, optionally, milk added. The resulting mixture is rolled and ‘conched’. Conching is a treatment whereby chocolate is kept in continuous movement to allow the cocoa mass to thicken and to develop into a homogenous substance. This process also allows volatile acids to escape, whereby the aroma is improved. Conching lasts for a number of hours. The name originates from the shell-shaped container in which the treatment took place in former days (‘concha’ being the Spanish word for shell). Depending on the desired taste, other ingredients may be added.

Finally, the hot chocolate mass must be allowed to cool slowly. This process, called ‘tempering’, is important for the right crystallization of the cocoa butter. After tempering, the chocolate can be poured into any desired form and hardened. During the hardening process the volume of the chocolate is reduced, allowing the chocolate to come out of the mould automatically.

White chocolate is made in a manner similar to “ordinary” chocolate, the only difference being that white chocolate does not contain any chocolate mass; just cocoa butter, sugar, milk and vanilla.

Specialization

Until the middle of the last century it was customary for manufacturers to do their own roasting, make semi manufactured cocoa products and, in addition, market their own consumer products. Those days are practically gone. At present two groups can be distinguished in the cocoa industry: producers of intermediate cocoa products and manufacturers of chocolate.

The Western Europe Cocoa Market

In the 2016/17 cocoa season, the European Cocoa industry ground over a million tons of cocoa beans, close to a third of the world cocoa production, with the Netherlands alone accounting for 550.000 tons, which makes it the second most important processor of cocoa beans in the world, closely following Côte d’Ivoire. Downstream, the Dutch cocoa trade and cocoa-processing industries together handle one million tons of Cocoa products. Other major European players in the cocoa trade and processing are Germany, the United Kingdom and France .

Cocoa mass

Cocoa mass

Some chocolate factories still grind cocoa beans themselves. Others buy cocoa mass from the cocoa press industries. But in all cases the factories purchase the extra cocoa butter needed to make chocolate. By far the greatest part of the cocoa mass is processed into cocoa butter and cocoa powder.

Cocoa butter

World-wide, the annual trade of cocoa butter exceeds 800,000 tons on average.

In Europe, the most important exporters are the Netherlands and France; the top buyers are Germany, Belgium, the Netherlands and France.

Cocoa powder

The Netherlands is the world’s market leader for cocoa powder with an export share of about 35%. Major outlets are the United States, Germany, Spain, Russia, Belgium and France.

Legislation

In most European countries and the United States chocolate is legally protected as a product. The minimum percentage of solid cocoa ingredients is determined by law.

European Directive 2000/36/EC only allows the addition of up to 5% of vegetable fats other than cocoa butter in the weight of the end product. Should this percentage be above 5%, the product may not be called chocolate.